Nickel Foam Filter Catches, Heats and Kills the Virus and other Pathogens

Researchers from the University of Houston, in collaboration with others, have designed a “catch and kill” air filter that can trap the virus responsible for COVID-19, killing it instantly.

Zhifeng Ren, director of the Texas Center for Superconductivity at UH, collaborated with Monzer Hourani, CEO of Medistar, a Houston-based medical real estate development firm, and other researchers to design the filter, which is described in a paper published in Materials Today Physics.

The researchers reported that virus tests at the Galveston National Laboratory found 99.8% of the novel SARS-CoV-2, the virus that causes COVID-19, was killed in a single pass through a filter made from commercially available nickel foam heated to 200 degrees Centigrade, or about 392 degrees Fahrenheit. It also killed 99.9% of the anthrax spores in testing at the national lab, which is run by the University of Texas Medical Branch.

“This filter could be useful in airports and in airplanes, in office buildings, schools and cruise ships to stop the spread of COVID-19,” said Ren, MD Anderson Chair Professor of Physics at UH and co-corresponding author for the paper. “Its ability to help control the spread of the virus could be very useful for society.” Medistar executives are is also proposing a desk-top model, capable of purifying the air in an office worker’s immediate surroundings, he said.

Ren said the Texas Center for Superconductivity at the University of Houston (TcSUH) was approached by Medistar on March 31, as the pandemic was spreading throughout the United States, for help in developing the concept of a virus-trapping air filter.

Luo Yu of the UH Department of Physics and TcSUH along with Dr. Garrett K. Peel of Medistar and Dr. Faisal Cheema at the UH College of Medicine are co-first authors on the paper.

The researchers knew the virus can remain in the air for about three hours, meaning a filter that could remove it quickly was a viable plan. With businesses reopening, controlling the spread in air conditioned spaces was urgent.

And Medistar knew the virus can’t survive temperatures above 70 degrees Centigrade, about 158 degrees Fahrenheit, so the researchers decided to use a heated filter. By making the filter temperature far hotter – about 200 C – they were able to kill the virus almost instantly.

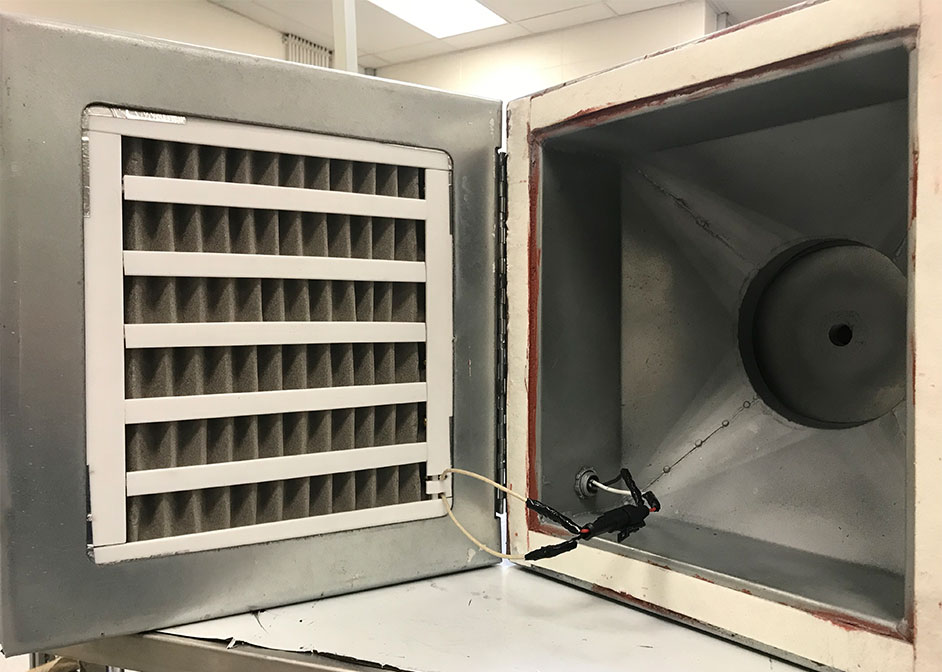

Ren suggested using nickel foam, saying it met several key requirements: It is porous, allowing the flow of air, and electrically conductive, which allowed it to be heated. It is also flexible.

But nickel foam has low resistivity, making it difficult to raise the temperature high enough to quickly kill the virus. The researchers solved that problem by folding the foam, connecting multiple compartments with electrical wires to increase the resistance high enough to raise the temperature as high as 250 degrees C.

By making the filter electrically heated, rather than heating it from an external source, the researchers said they minimized the amount of heat that escaped from the filter, allowing air conditioning to function with minimal strain.

A prototype was built by a local workshop and first tested at Ren’s lab for the relationship between voltage/current and temperature; it then went to the Galveston lab to be tested for its ability to kill the virus. Ren said it satisfies the requirements for conventional heating, ventilation and air conditioning (HVAC) systems.

“This novel biodefense indoor air protection technology offers the first-in-line prevention against environmentally mediated transmission of airborne SARS-CoV-2 and will be on the forefront of technologies available to combat the current pandemic and any future airborne biothreats in indoor environments," Cheema said.

Hourani and Peel have called for a phased roll-out of the device, “beginning with high-priority venues, where essential workers are at elevated risk of exposure (particularly schools, hospitals and health care facilities, as well as public transit environs such as airplanes).”

That will both improve safety for frontline workers in essential industries and allow nonessential workers to return to public work spaces, they said.

- Jeannie Kever, University Media Relations