Advancing Sustainable Low-Carbon Energy through Convergence

Ramanan Krishnamoorti 1, Jim Lawnin 2, Patrick Lewis 2, Charles D. McConnell 1

1. UH Energy, University of Houston

2. SVG Energy

Executive Summary

Accelerating the development and deployment of sustainable low-carbon energy solutions is required to continue to grow the availability of affordable, reliable and environmentally responsible energy for all, and make the US lead the energy transition world. The convergence of advancing the science and engineering of energy and sustainability, including carbon management, renewable energy, alternate fuels such as methanol and hydrogen, energy storage, and the circular economy, is necessary for driving this acceleration. Moreover, their alignment with policy and social drivers such as human behavior are crucial. Perhaps, the strongest accelerator for the transition relies on developing capabilities and competencies of the workforce with interdisciplinary tools. These include big data analytics, the integration of real-time artificial intelligence and machine learning with virtual and augmented reality to advance decision-making, and advanced technologies These technological and workforce assets must be complemented by aligning regulatory policy, public policy and business policy to improve and enhance the rapid adoption of such a sustainable energy paradigm.

Four distinct areas that contribute to the low-carbon energy systems of the future are seen as crucial accelerators of the energy transition: (a) Greenhouse gas mitigation through carbon capture, utilization and storage; (b) Process efficiency and process electrification; (c) Integration of renewable energy and incorporation of alternate fuels; and (d) Circular plastics and chemicals. The study here identifies tracks within these areas and crosscutting these areas that highlight convergence of scientific themes and their social drivers with the ambitious goal of leading to “Net Zero by 2050”. However, for significant progress to be made in the short-term and provide a solid basis for the future, four elements must be addressed simultaneously:

- (i) Establishment of crucial commercial deployments of carbon mitigation measures including circular plastic technologies, early successes of process efficiencies through electrification, and integration of renewables into a stable and reliable energy supply chain;

- (ii) Development of hardware infrastructure networks for the transport of carbon dioxide, alternate fuels, and electricity that underscore the ability to generate or use these in modular and distributed sites;

- (iii) Harmonization of public and regulatory policy drivers from the local to the national scales and across value chains with the intent to decarbonize the energy sector while maintaining affordability and reliability; and

- (iv) Development of an effective and nimble multi-disciplinary workforce that can adapt to a rapidly changing energy sector and further encourage and build awareness and knowledge across the population.

The study has identified 18 tracks of convergence enhanced fields in the four pillars that will rapidly accelerate acceleration the energy transition. The issues of improving efficiency, integrating renewables, adopting decarbonization and measuring it along with shifts in policies and social behaviors crosscut these tracks. The underlying interactions across those tracks and pillars and the connective tissue of enabling technologies and policies will define the pace of the energy transition. A significant challenge that the impending energy transition must confront is raising the awareness of a broad public and readying a workforce that is ready to integrate broad and disparate issues of science, technology and societal changes, and yet be nimble to adopt advances from adjacent spheres of influence.

Contents

I. Greenhouse Gas Mitigation: Carbon Capture, Utilization and Storage 6

I.A: Carbon Capture 7

I.B: Transportation of Methane and CO 2 8

I.C: Utilization of Methane and CO 2 8

I.D: CO 2 Utilization & Sequestration: Enhanced Oil Recovery and Storage 9

I.E: Technology and Policy Roadmaps for Rapid Commercialization 9

II. Process Efficiency and Process Electrification 10

II.A: Grid Efficiency & Integration of Renewables through Expanding Digitization 10

II.B: Energy Efficiency Improvements in Existing Oil Refineries, Chemical Plants, and Oil & Gas Production 11

II.C: Solar Thermal Heating for the Process Industries 12

III. Integrating Renewables and Alternate Fuels: 13

III.A: Convergence Acceleration of Wind and Solar 13

III.B: Renewable Geothermal Energy 14

III.C: Hydrogen for transportation 15

III.D: Hydrogen as an industrial fuel 16

III.E: Convergence Acceleration of Methanol 17

IV. Circular Plastics and Chemicals: 17

IV.A: Advanced Recycling of Plastics 18

IV.B Increasing Penetration of Mechanical Recycling: 18

IV.C: Distributed Waste Processing 19

IV.D: Plastics to Hydrogen: 19

IV.E: Technology and Policy Roadmaps for Global Technology Collaborative: 20

A. Introduction

In the era of accelerating climate change and the clear reality that we are at a critical stage of the energy transition, the development and deployment of sustainable low-carbon energy solutions is front and center. This energy transition will demand affordable, reliable and sustainable energy to address global energy poverty and fuel economic growth (Figure 1). This emerging energy transition therefore requires a lower carbon future, and underpinning the transition is the reality that affordable, equitably accessible and cost competitive options are essential to sustainability.

The convergence of advancing the science and engineering of energy and sustainability, including carbon management, renewable energy, alternate fuels such as hydrogen, energy storage, and the circular economy and their alignment with policy and social drivers, are crucial to drive the development of sustainable, reliable and affordable energy and the energy transition. Moreover, the development of the capabilities and competencies of the workforce and evaluation tools are essential enablers of this transition. These include big data analytics, the integration of real-time artificial intelligence and machine learning with virtual and augmented reality to advance decision-making, and advanced technologies that offer significant opportunities that address the decarbonization of energy resources and improve the air, water and land environment. These technological and workforce assets must be complemented by aligning regulatory policy, public policy and business policy to improve and enhance the rapid adoption of such a sustainable energy paradigm.

Figure 1. The key attributes of a sustainable low-carbon energy system are that energy should be accessible & reliable, affordable, and environmentally responsible.

Figure 1. The key attributes of a sustainable low-carbon energy system are that energy should be accessible & reliable, affordable, and environmentally responsible.

The field of sustainable low-carbon energy is ripe for rapid commercial development based on public – private partnerships that leverage private innovation with a focus on reducing costs and scaling deployment that is sensitive to ecosystem and geographical uniqueness [1] . While significant early stage science and technology developments have been undertaken over the last three decades, acceleration to demonstration and deployment will require convergence of disciplinary excellence and a focus on life cycle, path to commercialization and ensuring an ecosystem with demonstrable innovation policy including innovations in tax policy, market design, regulations, technology standards and environmental policy. Key social drivers to address include a broad suite of issues that encompass a social license to operate that covers understanding, evaluation and mitigation strategy of climate change impacts and emissions of greenhouse gases. Moreover, finding integrated modalities to address environmental, social and corporate governance (ESG) issues is becoming a critical step towards access to liquidity and financial stability.

The convergence of advancing the science and engineering of energy and sustainability, including carbon management, renewable energy, alternate fuels such as hydrogen, energy storage, and the circular economy and their alignment with policy and social drivers, are crucial to drive the development of sustainable, reliable and affordable energy and the energy transition. Moreover, the development of the capabilities and competencies of the workforce and evaluation tools are essential enablers of this transition. These include big data analytics, the integration of real-time artificial intelligence and machine learning with virtual and augmented reality to advance decision-making, and advanced technologies that offer significant opportunities that address the decarbonization of energy resources and improve the air, water and land environment. These technological and workforce assets must be complemented by aligning regulatory policy, public policy and business policy to improve and enhance the rapid adoption of such a sustainable energy paradigm.

1Deployment of Deep Decarbonization Technologies: Proceeding of a Workshop (2019).

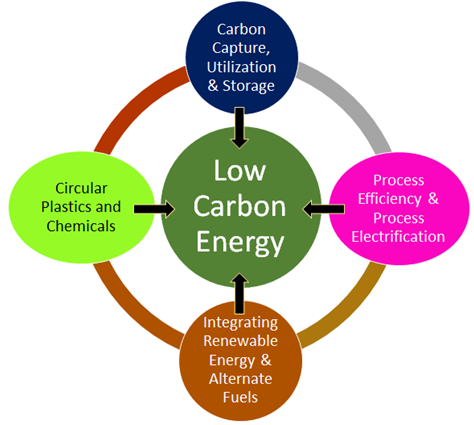

Figure 2. Components of the Sustainable Low-Carbon Energy ecosystem considered in this study.

Figure 2. Components of the Sustainable Low-Carbon Energy ecosystem considered in this study.

The decarbonization effort of the current energy systems and the continued growth of low-carbon energy systems are focused on four areas (Figure 2):

- Greenhouse gas mitigation: Carbon capture, utilization and storage;

- Process efficiency and process electrification;

- Integrating renewable energy and incorporating alternate fuels;

- Circular plastics and chemicals.

The crosscutting enablers for the advancement of these sustainable energy solutions include:

- Digital transformation including data analytics, machine learning, cognitive computing, virtual and augmented reality

- Automation and robotics, especially in industrial and hazardous operations

- Renewable energy integration, electrification of processes and process integration & intensification, including modularization

- Integration of carbon management

- Technology and social- and regulatory-policy roadmaps for technology deployment on a regional, national and global basis.

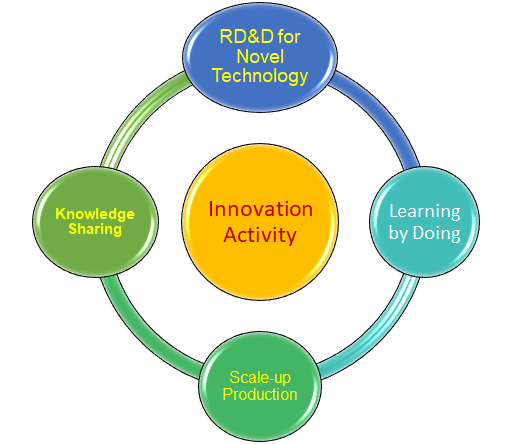

In this report, we identify and prioritize challenges and opportunities in the four selected areas for the decarbonization of the energy economy. These insights were developed through multiple virtual workshops carried out during Fall 2020. The contributors to these “Chatham House Rules” [2] based workshops included thought and subject matter experts from academia, national laboratories, start-up companies, and established industry. The discussions focused on identifying opportunities and barriers for the advancement of decarbonization pathways, the identification of convergence that could accelerate each sector, the participants in such convergence efforts and their unique contributions with a clear notion to identify success metrics in the short term (2 to 5 years) and in the long term (10 to 15 years). Specifically, we breakdown the innovation activities into (a) RD&D for novel technologies and improvements to existing technologies; (b) Learning-by-doing: Driving incremental improvements; (c) Scale-up production: Enabling economies of scale & building optimized value chains; (d) Knowledge sharing & policy drivers: across sectors & regions (see Figure 3).

2https://www.chathamhouse.org/about-us/chatham-house-rule

Figure 3. Innovation activities to accelerate the low-carbon energy economy.

Figure 3. Innovation activities to accelerate the low-carbon energy economy.

Development of sustainable energy paradigms that are economically realizable and reliable remains at the forefront of technological development and policy drivers. The most significant benefits over the next 2 to 15 years will stem from efforts focused on technological breakthroughs enhanced by convergence science, and engineering, with strong policy research and supported by understanding human behavior. These include improving the efficient use of energy (especially in industrial and transportation sectors), the integration of renewable energy platforms and process electrification, and a focused effort to lower emissions from energy consumption by a robust carbon capture ecosystem that ensures a business case for the capture, transportation and use of carbon dioxide.

There are significant variations in the path that different geographical regions will take towards decarbonization of the energy sector. However, the study also found that there are critical convergence innovations, in the areas of carbon mitigation, process efficiency, integration of renewables, electrification of various industry and uses, identification of alternate fuels, and the circular plastics and chemicals economy. These are detailed below as convergence tracks. Some of these include focused and distributed infrastructure, supply chain integration and optimization, public and regulatory policies that are informed by technology and the human – technology interaction, and most importantly through education of the public and an engaged workforce

C. Convergence Accelerator Tracks

I. Greenhouse Gas Mitigation: Carbon Capture, Utilization and Storage

For the last four decades, carbon capture, utilization and storage has been the central element of the research and development focused on decarbonizing the energy sector. A renewed focus on decarbonization and mitigating the release of methane into the atmosphere has accelerated the development of carbon mitigation technologies including carbon capture, utilization and storage (CCUS), as well as associated policy and social changes [3] . An impactful supply-chain network of carbon capture, transportation, utilization, and eventual sequestration that embraces technology, policy, practice and commercialization in geographically meaningful ways remains the biggest opportunity to rapidly decarbonize. A particularly important region for such a focus is the U.S. Gulf Coast, whose oil and gas activity, including refining and chemicals, accounts for nearly half the overall carbon footprint nationally and provides an excellent test-bed ecosystem for the commercial deployment of such efforts.

Decarbonizing the energy industry – the oil and gas segments of upstream, mid-stream and downstream, the petrochemicals industry, and the electric power industries, will be essential to early and impactful carbon emissions reduction [4] . The convergence of science, technology, policy and social sciences on decarbonization of the existing fossil-based energy industry is accelerated by the proximate supply-chain for CO 2. This includes the density of point source emissions, the required pipeline infrastructure to connect the sources and sinks, and geology necessary for the emissions storage.

However, CCUS does not simply enable the hydrocarbon industry to decarbonize; it enables the energy transition to effectively implement and deploy for impact. Several energy transition components will require CCUS for successful implementation, including: 1) the hydrogen economy and its impacts on the transportation marketplace and as an energy storage strategy; 2) the electrical grid and electricity use transformation (including electric vehicles) to a near zero emissions footprint; and 3) the petrochemical and plastics sector in terms of the circular economy and effecting a net zero approach.

4National Petroleum Council: Meeting the Dual Challenge A Roadmap to At-Scale Deployment of Carbon Capture, Use, and Storage (2019).

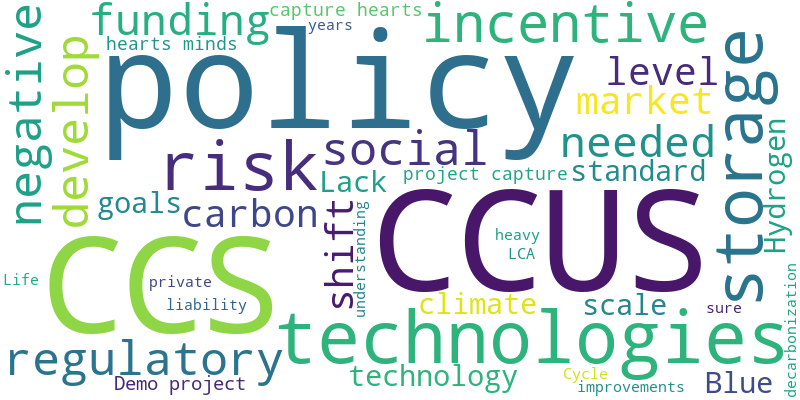

Figure 4. Word cloud responses focused on the opportunities and challenges in decarbonization driven by improvements in process efficiency and process electrification.

Figure 4. Word cloud responses focused on the opportunities and challenges in decarbonization driven by improvements in process efficiency and process electrification.

The immediate deployment of decarbonization in the hydrogen economy requires the transition from the existing base of natural gas based steam methane reforming (SMR) technology and the resulting CO2 emissions (“gray” H2) to the next generation of “blue” H2 where the SMR technology is equipped with carbon capture, which would then be supplied into the existing CCUS network. In the longer term, we anticipate a further shift in the hydrogen economy to electrolysis of water and completely fossil-fuel independent hydrogen generation. Such fossil-fuel independent, zero-carbon hydrogen is termed “green” H2. The path to a green hydrogen economy requires a scaled deployment of CCUS to deliver “blue” H2 as a first step, and a low barrier to develop the supply chain and infrastructure for a hydrogen economy.

Similarly, decarbonizing a growing electricity demand and moving to a 100% renewable gird requires large leaps of technology, policy, supply chain enablers and perhaps most importantly a very large global investment. One the other hand, moving to electricity supply that is 100% carbon free (not 100% renewable) has a lower barrier to realization. Electrons that come from baseload facilities (gas and coal based) that have already been installed can be made carbon-free though the use of CCUS and a comprehensive integration of that supply chain.

Conversion of the chemicals and plastics industries to use only renewable feedstock resources requires significant technology advances, changes in consumer behavior patterns and a supply-chain for feedstock and end-of-life that are still nascent. The circular chemicals and plastics economy, along with their effective decarbonization, will require a combination of process level CCUS technologies, adoption of electrification and integration of hydrogen into the ecosystem. The advancement of an effective CCUS value chain will most effectively advance the retooling of the chemicals and plastics industry.

I.A Carbon Capture

The large carbon footprint of existing electricity generation and industries are ideal opportunities for the deployment of point source carbon capture. The industrial community across the U.S and globally has focused on electricity generation from hydrocarbon feedstock, downstream refining, petrochemicals and materials manufacturing (including plastics, chemicals, metals and cement) to demonstrate and deploy carbon capture technologies (post combustion, pre combustion, and oxy fuel) over the last four decades. The biggest challenges for the increased deployment of carbon capture technologies lie in the high capital expense of such technologies, the energy needs for the operation of the process, and the absence of a robust infrastructure to transport and use or sequester the carbon.

The wide range of processes (including refining, chemicals, metal manufacturing and cement) that are amenable to industrial scale deployments of carbon capture and fiscal incentives to capture and store carbon provide a strong basis for the rapid growth of carbon capture and storage. There are potentially attractive opportunities for academia and the scientific community, as well as entrepreneurs and start-ups, to develop new carbon capture technologies that are robust, have a low energy footprint, and potentially extendible to gas streams with much lower concentrations of CO2. A particularly interesting approach is the application of direct air capture technologies. Some solutions are modular and scalable, integrated with renewable energy and located in proximity of eventual use or storage sites. This can make the approach cost-effective in the short term [5] .

Fugitive methane emissions from upstream oil and gas operations, as well as midstream transport and processing of natural gas, have become an even greater challenge because of the greenhouse gas intensity associated with methane. Opportunities to monitor and mitigate fugitive emissions of natural gas, as well as minimize the flaring of natural gas, remain outstanding issues around which significant societal pressure continues to build. Yet cost-effective technologies to continuously monitor and capture natural gas and reuse it for chemical or fuel value remain largely unsolved at the commercial scale.

For the cases of both CO2 and CH4 mitigation, it is clear that capture technologies must be more cost effective, have a lower energy footprint, be capable of handling streams with lower concentrations of these gases and less pretreatment, and be connected to the remainder of the supply chain, for the effective utilization and eventual storage or sequestration. The convergence of business principles, policy directives, societal pressures with the impending growth of process methods and detection techniques (for methane) can effectively increase the commercial deployment of these capture technologies.

The key deliverables in the short term include the identification of emissions processes, cost assessments for engineering and implementation, process integration, and intensification targets for industrial processes that can achieve the required reductions across industries and processes. In addition, technology development timelines and technology readiness level (TRL) roadmaps are required to plan the transformation over the short-, medium-, and long-term.

5Negative Emissions Technologies and Reliable Sequestration: A Research Agenda. National Academies of Sciences, Engineering, and Medicine; Washington (DC): National Academies Press (US); 2018 ISBN-13: 978-0-309-48452-7ISBN-10: 0-309-48452-9

I.B: Transportation of Methane and CO 2

The significant volume of fugitive emissions of methane from the various activities related to production of oil and gas as well as the distribution and use of natural gas, represent one of the most significant environmental challenges for the energy industry. Identification of leaks and quantitative measurements of emissions are essential to understand the extent of the challenge. Further, the use of those data enable proactive operations and maintenance and mitigation strategies. The ability to transform the measurement and analysis is fundamental to emissions reduction. Drones, airborne monitoring, data systems management, etc. are all opportunities. In addition, further expansion and integration of networks will require infrastructure analysis to optimize gathering and transport.

Similarly, enabling the transportation of CO2 (from points of capture to points of use or sequestration) requires advances in materials science for pipeline infrastructure, optimization of supply chain, expansion of CCUS network and the concept of common carrier transport for the vast volumes of CO2 that would be required to go from capture to geologic storage regimes. The ability to envision and optimize a national network, not just serving regional needs, but a network not unlike the interstate highway to serve the public good of CO2 emissions reduction is crucial to advance carbon mitigation. Moreover, regulatory and policy issues including right of way, access, permitting by rule, and ensuring the integrity of health-safety-environment processes must be implemented to meet requirements.

The convergence of leak monitoring and leak mitigation, uniform permitting and optimization of the supply chain and utilization is essential for the transportation of both methane and CO2. Partnerships of the various parties within the supply chain are required, and the networks must be optimized to ensure the most effective and reliable operation. Crucial to this are partnerships with industry trade associations such as the pipeline groups (e.g., INGAA) and materials research from organizations such as Battelle for integrity and measurement. The short-term goals of the work would include mitigation of methane leaks and the expansion of CO2 pipelines to lower the barrier for new capture and use technologies. The longer-term goal is to ensure an efficient network of CO2 pipelines and a regulatory policy that allows a common carrier concept to be realized.

I.C: Utilization of Methane and CO 2

Due to the highly stable nature of CO2, its conversion to chemical products is energetically intensive and therefore challenging to achieve economically. On the other hand, methane is highly reactive and the distributed processes of upgrading of natural gas to useful liquid products also remains challenging and difficult to achieve economically. Modular and intensified processes to make this conversion feasible have been demonstrated but have yet to be deployed on a commercial scale.

In the case of methane, the ability to aggregate and then convert the CH4 to useful products will require not only transformative methods to mitigate venting and leaking but also improve capture and enhance the conversion capabilities to fuels and chemicals. The two most prominent methods for the conversion of methane to liquid fuels are direct partial combustion of methane to methanol and the Fischer–Tropsch-like processes that convert carbon monoxide and hydrogen into hydrocarbons. While these have been demonstrated in large scale, using them in distributed, modular, and intensified processes remains technologically and commercially challenging. A significant opportunity remains in developing modular processes that are coupled with renewable energy generation and can be deployed economically and commercially.

A broad range of potential uses of CO2 have been conjectured and technologies developed to demonstrate their viability. However, the cost of capturing and generating pure CO2, cost of transporting it to points of use, the chemical stability of CO2, and the energy needed to convert it, have largely curtailed the effective uses for CO2 except as a physical agent including in enhanced oil recovery (EOR) (discussed below) and as a supercritical solvent. Some noteworthy chemical utilization of CO2 include the biochemical pathway to convert it to methanol, synthetic chemical methods to generate liquid fuels, the synthesis of plastics such as polycarbonates, and the manufacture of alternate building materials. In the short term the cost of supply of CO2 is the single biggest barrier to increasing breadth and extent of its use.

Utilization convergence in a partnership hub would call upon industry, national labs, entrepreneurs and start-ups, and academic leaders to advance the utilization of methane and CO2. To be effective this must integrate with the capture and transportation ecosystems. Deliverables would be breakthrough technologies and would require an open source structure for intellectual property (IP) in the early stages, and the ability to convert further TRL advances to investors and start-up companies. In the case of CO2 utilization, ultimately, obtaining some sort of verifiable certificate of permanent and effective sequestration will be a requirement, and methods to measure, verify and certify will need to be developed and delivered.

I.D: CO 2 Utilization & Sequestration: Enhanced Oil Recovery and Storage

Geological sequestration in saline aquifers and in depleted oil and gas reservoirs are seen as attractive opportunities to effectively remove CO2 from the environment. Additionally, mature oil and gas reservoirs that are post primary- and secondary- (water flood) production, in many cases, are opportune fields for CO2 based enhanced oil recovery leading to safe storage of CO2 in those reservoirs. The U.S. has huge storage capabilities, both onshore and offshore, either through direct methods or by enabling EOR. Moreover, the U.S. has demonstrated these technologies to ensure the safe and effective storage at scale for over five decades. The challenges to expansion of this effort are multi-pronged: the absence of full understanding of sub-surface transport and reactions in saline aquifers and complex geologies; the applicability of EOR to moderate temperature carbonate reservoirs and the sub-surface chemistries in those reservoirs; the expansion of the capture and transportation infrastructure to deliver, at scale, appropriate quantities of CO2; a well-quantified risk model for estimation of long-term risks and possible monitoring and mitigation steps; and perhaps most importantly, a clear articulation of the appropriate authority to “certify conformance” and the assignment of the risk associated with long-term storage of CO2 in the sub-surface.

The convergence of sub-surface characterization and modeling, along with reservoir management and monitoring, with supply chain optimization, risk modeling, and clear (regulatory and public) policy development, along with continued engaged incentive processes for the safe and reliable storage of CO2, will advance this important tool for decarbonization of the energy industry. The development and improved implementation of the 45-Q policy in the U.S. proved a rapid accelerant for the expansion of CO2 storage. However, the policy as applied now does not provide the stability for long-term continued expansion. Likewise, connecting capture and transportation ecosystems with the storage and use for EOR ecosystems and ensuring partnership with oversight bodies will be crucial. Development of a strong and committed ecosystem for safe and reliable storage will advance the decarbonization of the current energy system in the short-term. In the longer term, it will lead to paths for reducing the aggregated carbon already placed in the environment.

I.E: Technology and Policy Roadmaps for Rapid Commercialization

A common theme emerged in all of the decarbonization strategies: the absence of clear technology and policy roadmaps towards commercialization for the various sectors and further the inter-connectivity of those roadmaps both in terms of strategies and geographies. Often it has been considered that the energy transition pathways are likely to be local or regional in scope. However, increasingly it has become clear that, because of the large investment associated with the energy and decarbonization infrastructure, there must be connectivity between these different regional efforts to optimize the networks and reduce costs. Such roadmaps must demonstrate convergence of public policy, regulatory framework, and legal constructs that clarify and bound responsibilities. This will enable businesses to invest with the risks understood and effectively priced in. These roadmaps must be developed in the short term and must be updated periodically to ensure accelerated advancement of the energy transition.

II. Process Efficiency and Process Electrification

Improving process efficiency is seen as the most cost effective way to decarbonize the energy and industrial landscape. Moreover, electrification of processes, especially refining and chemicals manufacturing, can potentially lead to a significant reduction of the carbon footprint associated with these industries. Electrification of processes also allows for a longer term goal to use renewable energy to power all of these processes.

II.A: Grid Efficiency & Integration of Renewables through Expanding Digitization

Growth of electricity from renewable sources, especially intermittent solar and wind, is hampered by the limited ability of electric grids to handle load variations over both short (minutes, hours) and long (days, weeks, seasons) time scales. Most proposed solutions rely heavily on currently expensive energy storage options, notably grid scale batteries, hydrogen, and compressed air energy storage (CAES). While some storage will be essential, the growing deployment of digital technologies within the power sector provides a unique opportunity to manage the grid more effectively. Moreover, access to large data sets, much of it in near real-time, through the entire supply chain will be another unique opportunity. Harnessing this information can reveal new opportunities in both supply-side and demand-side management, increased integration of renewables, higher efficiency, and reduced costs in existing grids, and lower-cost options for revamps and new grid systems. Current barriers include existing policies on transmission grid siting; regulations for grid operations; lack of financial incentives for grid operators and lack of business drivers; and dominance of monopolistic vertically integrated utilities.

Expanding grid efficiency and integrating renewables requires multi-discipline engagement across power engineering, data analytics, control systems, business analytics, public policy, renewable energy and technology. Research would focus on grid variability and stability, impact of increased renewables and management strategies; market analysis; pricing mechanisms; and public policy directives.

Stakeholders representing the range of activities in the supply chain and with diverse interests need to collaborate. These include electrical utilities, grid operators and regulators, renewable energy developers, technology vendors, government agencies, and academia. The electric utilities bring a deep knowledge of their markets, and the capabilities and limitations of their physical systems. Grid operators can provide electrical system data at a regional level, which complements information from individual utilities. Renewable energy developers and technology vendors together bring knowledge of key markets, as well as the capabilities and limitations of existing (and potentially future) technologies; while government agencies and grid regulators provide policy insights, along with experience in implementation and enforcement. Academic research brings an objective perspective to the analysis of information and the development of innovative options. In addition, bringing the parties together creates opportunities for business collaborations, which provide a strong incentive for engagement and rapid deployment of the best opportunities.

Better use of digital assets will improve flexibility within existing grid systems. This will reduce curtailment of renewable electricity by 20% within 3 years, leading to higher efficiency, reduced greenhouse gas emissions, and reduced costs. Initial studies will focus on a single existing grid system. Over time, learnings will be transferred to other grids, business collaborations will develop, and better options for integrating electric generation, storage, and distribution will emerge, guided in large part by analysis of data from existing grids. This will lead to a fully decarbonized grid by 2050.

Figure 5. Word cloud responses focused on the opportunities and challenges in decarbonization driven by improvements in process efficiency and process electrification.

Figure 5. Word cloud responses focused on the opportunities and challenges in decarbonization driven by improvements in process efficiency and process electrification.

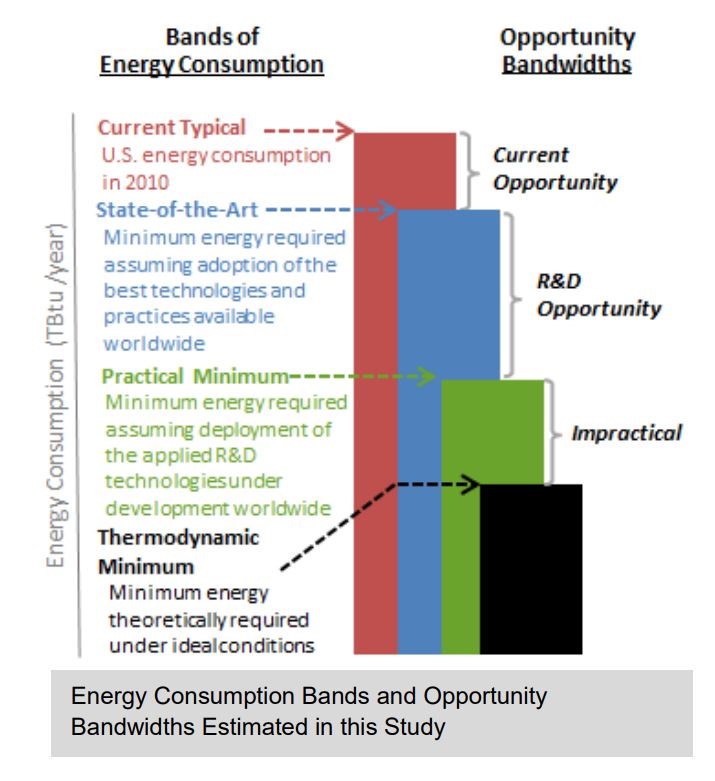

II.B: Energy Efficiency Improvements in Existing Oil Refineries, Chemical Plants, and Oil & Gas Production

Continuous energy intensity improvement is an established goal in most large integrated oil companies, as well as chemical and petrochemical companies. In the 1990s and early 2000s, annual energy intensity improvements of 2-3% were not uncommon; and over time, some companies achieved cumulative improvements of 30-40%, or more. However, in recent years improvements have declined to <1% in most companies, and in some cases energy intensities have actually increased. However, best estimates indicate that the potential for improvement in oil refineries using existing technologies is at least 14%, with a further 26% available as new technologies emerge (Figure 6); and the potential in chemicals is even greater [6] . There is an opportunity to restore the rate of improvement to its earlier pace. Many options for improving energy intensity are known, but they are difficult to justify financially. Additional barriers include the time required to design and implement physical changes at large refineries and chemical plants, and uncertainties in energy prices.

Solving this problem depends on the convergence of chemical sciences and engineering, data analytics, business, and public policy. Many known options for efficiency improvements can be made financially attractive with an appropriate business and regulatory environment. In addition, ongoing technology research, such as advances in catalysis, process intensification, modularization and process integration, will lead to new solutions for industry-wide energy efficiency problems, and new policies will incentivize mass deployment of energy efficient technologies.

This program requires engagement across engineering, business, data analytics, public policy, and technology. Participants include:

- The large corporations that own and operate the producing facilities, which provide both the data upon which the program is based, and the testbeds where solutions are deployed;

- Energy management specialists and technology developers, who possess the knowhow and create the technologies that are required to achieve efficiency improvements;

- Academic research, which brings an objective perspective to the analysis of information and the development of innovative options; and

- Policy-makers and regulators, to design and implement strategies that incentivize progress in this area.

The early results (first 2-5 years) of this convergence will be a greater focus on operating efficiencies, and small projects that can be implemented without lengthy engineering efforts or plant turnarounds. Examples include implementation and improvement of energy efficiency programs (e.g., ISO 50,001) and deployment of real time systems for detecting methane leaks, as well as monitoring, controlling and optimizing process plants, and investment in recovering stranded gas (e.g., for power generation), replacing flaring. Over time, the focus will shift to new solutions growing out of R&D activities, and major projects to upgrade or replace existing facilities. The overall impact will be a reduction in energy intensity of about 30% by 2040, compared to 5-10% based on the current trajectory.

6USDOE-EERE, Bandwidth Study on Energy Use and Potential Saving Opportunities in U.S. Petroleum Refining (2015)

Figure 6. Potential energy efficiency improvement bandwidths (Source: 6).

Figure 6. Potential energy efficiency improvement bandwidths (Source: 6).

II.C: Solar Thermal Heating for the Process Industries

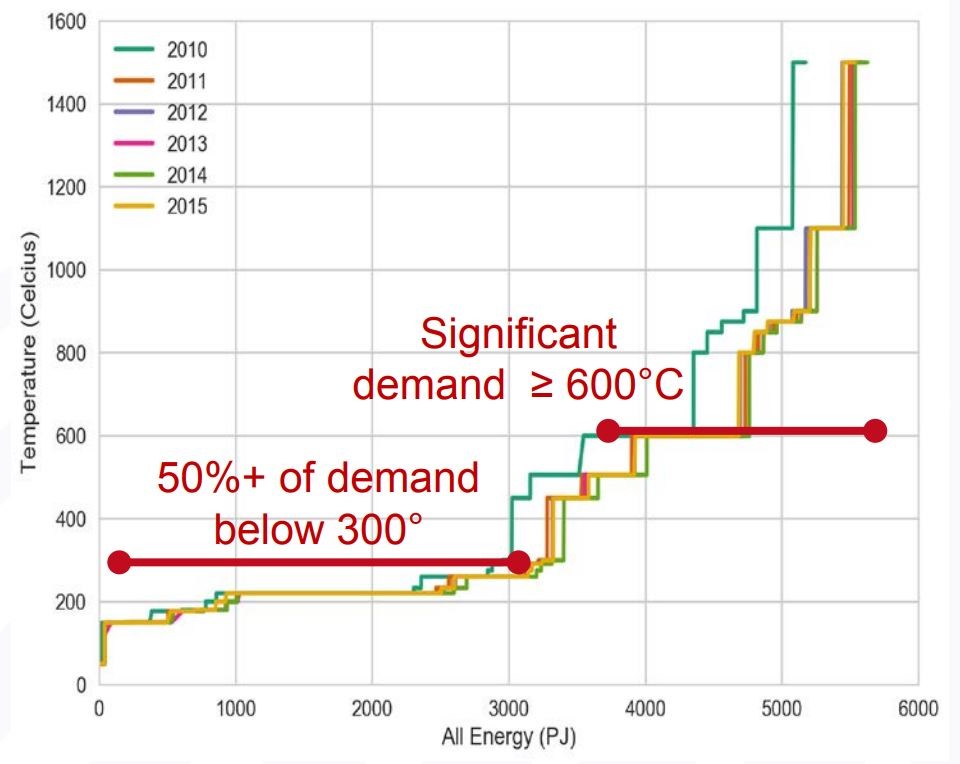

Solar thermal heating presents a significant opportunity to decarbonize in the process industries. The energy usage in most large chemical and refining processes is dominated by heating needs. The heat is generally obtained by burning fossil fuels, either in boilers or furnaces. Solar thermal sources could be used for many of these heating demands [7] – especially those below 300⁰C (572⁰F), which represents about 50% of the total demand (see Figure 7).

The two main strategies that have been proposed for decarbonizing these services are electric heating (using renewable power, usually solar or wind), or replacement of fossil fuels with “green” hydrogen – which is an indirect form of electrification. However, these technologies are inherently inefficient. The best commercial PV cells are only 23% efficient; and the overall energy efficiency of making and burning hydrogen is even lower. In contrast, current solar thermal systems can have efficiencies of 70% or more. Therefore, the land area required by a solar thermal system less than ⅓ of that required by a solar PV system for the same thermal capability. There are significant technical and financial risks and barriers, which could be mitigated with appropriate policies. Like most renewable energy sources, solar thermal is intermittent. This can be mitigated – at a significant cost – with thermal storage. The technology is also very dependent on weather conditions, and hence on climatic regions. Even though the land area is much smaller than that for an equivalent PV system, it is still large compared to the size of most process facilities. Appropriate public policies will be needed to overcome these barriers and mitigate the technical and commercial risks.

Although many forms of solar thermal technology have been developed, they have never been directly used to meet large process heating demands in chemical and refining processes. Capturing this opportunity depends on the convergence of engineering, business, and public policy. Owners and operators of process facilities are essential partners, as they provide both demonstration platforms and ultimate users of the technology. Engineering R&D will be a key component of the program, to overcome the significant technical challenges of integrating solar thermal heating into large process plants. Additionally, the broad use of combined heat and power systems in many refineries and chemical plants creates a high barrier for entry for solar thermal-based industrial heating. Government and policy-makers have a key role in providing options to promote the technological developments, and de-risk investment.

The early stages of this track will focus R&D and engineering feasibility studies, and policy development, with goal of deploying demonstration projects by the end of year 3. The overall impact by 2050 would be use of solar thermal energy for 50% of heating requirements in the US oil refineries and chemical plants.

The early results (first 2-5 years) of this convergence will be a greater focus on operating efficiencies, and small projects that can be implemented without lengthy engineering efforts or plant turnarounds. Examples include implementation and improvement of energy efficiency programs (e.g., ISO 50,001) and deployment of real time systems for detecting methane leaks, as well as monitoring, controlling and optimizing process plants, and investment in recovering stranded gas (e.g., for power generation), replacing flaring. Over time, the focus will shift to new solutions growing out of R&D activities, and major projects to upgrade or replace existing facilities. The overall impact will be a reduction in energy intensity of about 30% by 2040, compared to 5-10% based on the current trajectory.

7Robert Margolis, Colin McMillan, Parthiv Kurup, “Solar for Industrial Process Heat” SETO CSP Program Summit 2019 Oakland, CA March 19, 2019

Figure 7. Heating demand by Process temperature (Source: 7).

Figure 7. Heating demand by Process temperature (Source: 7).

III. Integrating Renewables and Alternate Fuels:

As alluded to above, renewable energy has made significant penetrations into the U.S. economy, and broadening its impact is going to require heightened focus on its integration into industrial and commercial processes. A significant opportunity to expand renewables lies in the area of inexpensive, reliable and integrated energy storage which, in spite of significant technological and commercialization breakthroughs, has remained stymied largely because of the absence of incentives or policy drivers. Below we discuss other key opportunities, including convergence acceleration of wind and solar, geothermal energy, hydrogen both for transportation and as an industrial fuel, and methanol as alternate pathways to decarbonize the economy.

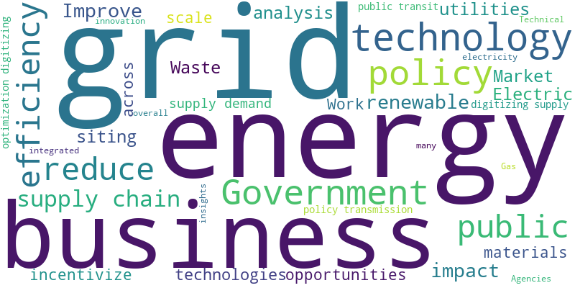

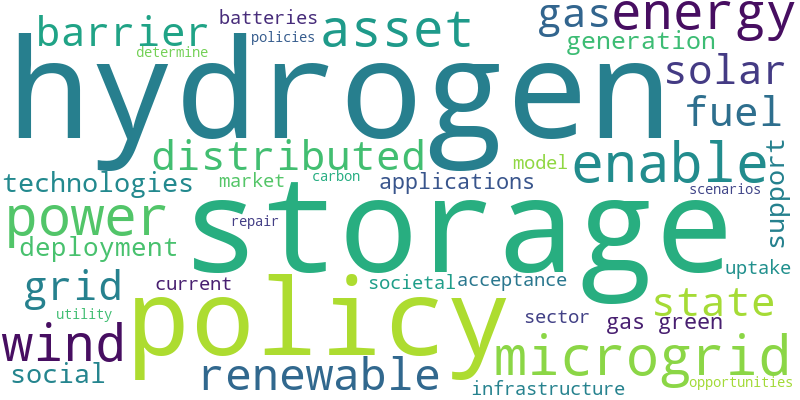

Figure 8. Word cloud responses in the focused area of integrating renewables and identifying alternate fuels as opportunities and challenges in a decarbonized energy economy.

Figure 8. Word cloud responses in the focused area of integrating renewables and identifying alternate fuels as opportunities and challenges in a decarbonized energy economy.

III.A: Convergence Acceleration of Wind and Solar

Wind and solar enjoy considerable public support and the societal push to decarbonize energy production is driving their deployment. Onshore wind and solar (PVs, both rooftop and community, and solar thermal) have matured and become cost-competitive with hydrocarbon-derived electricity. Now advances in improved generation of distributed and concentrated renewable generation, battery storage, grid integration and optimization, and progress on offshore wind offer the biggest opportunities for research, development and deployment. Current technical barriers focus on the intermittency of electricity generation, the high cost and environmental impact of energy storage and grid connectivity challenges. Amongst non-technical issues, permitting, licensing and procurement regulations, expiring federal tax credits fueling worries of market bubbles and stranded assets, and sensitivity to the global supply chain are the most noteworthy.

Acceleration of advancing generation efficiency and grid optimization is likely through technologies such as robust multi-layer PV, reconfigured wind turbines and improved grid architecture and connectivity. More energy-efficient conversion will especially benefit solar thermal and address the sensitivity of heating fluids to diurnal shifts, driving broader deployment for multiple uses, including residential, commercial and industrial use. For solar PV and wind energy, capitalizing on efficient algorithms, optimized hybrid models for better grid connectivity at utility-scale and micro-grid level will be critical. Further, policies simplifying permitting, licensing, and procurement to allow DERs aggregators to compete in regional wholesale electricity markets will be necessary. Debottlenecking grid- and storage-related challenges will also help the integration of renewables with hydrogen and electrification of the transportation fleet. In heavy demand centers like cities, distributed solar PV is emerging as a natural choice with rooftop or building-integrated solutions. Tracking the uptake and maintaining data on distributed PV will further strengthen the case for installation and inform policymakers on resource distribution. With commercial- and residential-scale generation, fixed costs of utilities are spread across a smaller base, which raises the cost to the ratepayer. Policymakers will need to address the equity concerns arising from the price disparities, as many of those relying on the grid are taxpayers who cannot afford to build their own energy farm.

Deploying and integrating offshore wind with the grid could greatly benefit from technologies and policy drivers that can utilize existing offshore oil and gas infrastructure for generation and connectivity with the onshore demand centers. Convergence of advanced wind turbine design, resilient offshore structures, artificial intelligence, monitoring through drones, and predictive maintenance will be beneficial in both offshore and onshore environments, and will reduce operation and maintenance expenses. The environmental impact from mining for rare earth minerals, recycling old wind turbine blades, land footprint, land grabs and human rights violations, and addressing societal acceptance issues, will require societal shifts built into broader policy mechanisms. Breakthroughs can emerge at the intersection of renewables with waste management for hydrogen production, and with negative emissions that use technologies like direct air capture to drive down the energy costs of carbon capture.

Renewable energy generators, supply chain companies, investor groups, utilities and policymakers will need to join forces on regulatory issues related to licensing and permitting to accelerate new capacity additions, especially in offshore environments. Moreover, policy changes are needed to address the phasing out of wind and solar tax credits and the temporary investment inertia this may create. Parallel efforts by businesses and policymakers must focus on enabling DERs and developing pricing structures that provide a level playing field for technologies. The foundational research for these models can be supported by national laboratories and academic institutions. In addition, collaborations between renewable companies, storage and battery companies, automakers and policymakers will help develop regional and national recycling standards and materials recovery standards for renewables infrastructure. Behind the meter accounting from distributed generation and grid digitization will require partnerships between renewable producers at the utility, micro-grid, and residential scales. Policymakers and technology companies also need to collaborate in increasing efficiency, cybersecurity, transparency and data management. Partnerships between oil and gas companies and offshore wind companies will allow the utilization of offshore platforms for wind generation, while also retaining the original workforce. Finally, all stakeholders must engage with environmental groups, human rights, and law firms to develop stricter standards for land utilization. This partnership can also benefit community engagement on NIMBY-related challenges and ensure that communities that cannot finance their own distributed generation are not disproportionately impacted.

By 2030, wind and solar can each account for 20% of the US energy mix. Deliverables include developing standardized energy storage modules at different scales ranging from micro-grid to utility-scale, better business model and technical standards for DERs, optimized and safe algorithms for micro-grids, and scaling up distributed generation of wind and solar. Policy prioritization must include workforce upskilling and development, addressing licensing, human rights, and environmental concerns. Integration with data management and cybersecurity will strengthen optimized grids, automation, and data tracking from distributed generation.

III.B: Renewable Geothermal Energy

While geothermal energy has been a prolific resource in advantaged geographies, the potential for deep geothermal remains underdeveloped. Geothermal energy’s biggest opportunity lies in repurposing depleting oil/gas wells through advanced drilling methods to allow for deep geothermal energy extraction and thus generate electricity. However, current barriers include high drilling costs to reach higher temperature reservoirs leading to high capex and limited technology for drilling in harsh environments. Moreover, regulatory issues for the safe repurposing of depleted wells are yet to be fully tested and establishing limitations of liability are crucial.

Convergence between geothermal and oil and gas companies can provide many learning opportunities. For harsher environments of high temperature and pressure, and dry formations with low permeability, enhanced geothermal systems through hydro-shearing are being explored. With the oil and gas industry’s extensive experience in drilling and producing fluids from such environments, scaling enhanced geothermal synergies can help retain knowledge from the current workforce and utilize existing infrastructure. Partnerships between geothermal companies, oil and gas operators, investor groups, utilities, policymakers and regulators, especially for issuing permits for subsurface exploration can help with the immediate technology and cost challenges. This would allow geothermal to become a significant source of baseload electricity in the US by 2050. Given the nascency of this field, it may require more time than 5 years to develop a nuanced understanding of all opportunities and challenges and to achieve measurable social impact.

III.C: Hydrogen for transportation

Transportation is one of the most important areas for decarbonization. While there has been significant advancement of electrification of light duty and passenger vehicles, medium- and heavy-duty vehicles, and in some markets light duty vehicles, are well suited for hydrogen. Moreover, the energy-dense marine and aviation sectors also present unique opportunities for hydrogen to support the energy transition.

In terms of hydrogen production, steam methane reforming (SMR) is the most widely used technology. A small fraction of the current production is met by electrolysis, which is becoming increasingly attractive as the cost of renewable energy declines. Opportunities and barriers along the supply chain, including the end-user, must be addressed to scale hydrogen effectively. Current barriers associated with production include the emissions associated with gray/brown hydrogen produced from natural gas and coal and hydrogen’s price sensitivity to both. The high cost of deploying hydrogen infrastructure and the risk of locking in capex has limited its scalability and leads to high transport and storage costs. Licensing and permitting barriers have also recurrently skewed project economics and timelines. Inadequate policies and social drivers have hindered demand and broad public adoption, which in turn has decreased the utilization rate of infrastructure and increased deployment costs.

Hydrogen production can be low-carbon when combined with CCUS and renewables, thereby converting gray/brown hydrogen to blue and green, respectively. In both cases, systems analysis and comprehensive LCAs are required to understand the costs and opportunities of such synergies. The growth of hydrogen will result in utilizing existing production infrastructure and workforce. Moreover, new production technologies like plasma-enhanced gasification of municipal solid waste (including plastic waste) offer an excellent convergence opportunity.

To scale up efficiently, we must address the key three aspects of hydrogen generation, transportation and use technologies. In the absence of a safe, affordable and reliable transport system, we must consider technologies that would lead to hydrogen being produced close to where it can be used, On the demand side, social shifts can be catalyzed through policies for public education and community-level efforts to encourage the uptake of hydrogen, address safety concerns, and drive broader acceptance for pipeline infrastructure to overcome social drivers such as NIMBY. To maximize the utilization of current infrastructure, regulations on who can handle hydrogen along the delivery network and at refueling stations, how much hydrogen can be present in existing pipelines, and leak detection must be revised. Decarbonization targets of the IMO Greenhouse Gas Reduction Strategy are expected to drive the demand for hydrogen in shipping, but international standards addressing origin, purity, and design specifications must be established. Demonstration projects have been successful for small-scale hydrogen planes, but significant R&D is required for adoption across the aviation sector. Along with policies for social change, critical economic policies must include tax incentives for hydrogen vehicles, portfolio standards, and infrastructure enablers to drive down costs. A price on carbon will dramatically alter the supply and demand landscape for hydrogen across all sectors, and impact action in all other policy spheres. For convergence with CCUS, policies must also connect hydrogen production sites to CO2 storage and utilization pathways, while policies for renewable energy directed towards tighter grid integration will accelerate electrolysis scale up.

Hydrogen’s versatility is ideal for multi-stakeholder involvement and partnerships, such as those along the supply chain from production, retail and distribution, automobile, trucking, marine, aviation, renewables, plastics, and municipal waste management companies. State and federal policymakers and regulators will shoulder much of the near-term work to catalyze the technology and business changes outlined above. Advocacy groups will be vital for driving community participation and ensuring equity concerns from policy shifts are addressed. Investor groups will facilitate scaling up and market confidence for end-users from all markets. National laboratories and academic institutions will support the partnerships through engineering, legal, business and policy R&D, and collaborate on communications efforts to aid social acceptance. International partnerships (e.g., with the EU) to share lessons on hydrogen can help avoid past missteps. It would also be essential to engage with standard-setting bodies like ISO and ANSI.

The immediate focus must be to stimulate demand, outline and consolidate a hydrogen roadmap for the near and long term, and to de-risk investments and scaling up. Thus, key deliverables include scaling up current technologies on both a centralized and a distributed basis, driving down costs by 25-30% in the next ten years through cross-sectoral integration, addressing the carbon footprint from gray/brown hydrogen, using current infrastructure, and catalyzing policy and social shifts.

III.D: Hydrogen as an industrial fuel

Currently, the strongest demand for hydrogen is from the process industry, specifically in the production of methanol, ammonia, steel, and in refineries. Even though production is at scale in the industry, hydrogen is produced from natural gas, coal, and oil using well-established technologies such as steam methane reforming. Thus, the biggest challenge is mitigating the associated carbon footprint from gray/brown hydrogen and producing low-carbon hydrogen.

Efficiency gains and fuel switching alternatives in most industries have already been explored and achieved, thereby limiting pathways for decarbonization. Convergence with CCUS to capture the associated emissions at source or using renewables to produce low-carbon hydrogen from electrolysis can aid the transition. The industry produces highly concentered streams of CO2 which offer the lowest capture costs for CCUS. Most oil refineries already have SMR units in place, which would also make CCUS the natural choice. Given the nature of the refining industry in terms of its tight margins, connecting the captured CO2 to markets where it can be utilized would help maintain competitiveness. For methanol and ammonia, in addition to CCUS retrofits, electrolytic hydrogen or using biomass feedstocks can reduce the associated carbon footprint. For steel production, direct reduction of iron with CCUS or by using electrolytic hydrogen as the only reducing agent can reduce the carbon footprint. However, renewables-based electrolytic hydrogen can only mitigate a part of the emissions. To produce carbon-free steel, process emissions embedded in the extraction and generation of iron ore and limestone will require integration with CCUS.

Policymakers have a critical role in the convergence opportunities for hydrogen’s industrial use. A price on carbon will make the economics attractive, mitigate higher production costs from retrofits, and strengthen the business case for CCUS. Additionally, enabling fledgling markets based on CO2 utilization will rely entirely on policy support in the near-term. In areas of process changes, such as that of direct reduction of iron with electrolytic hydrogen, funding for R&D, and scaling demonstration projects to deployment will require adequate policy support. Portfolio standards for low-carbon industrial products will also help drive demand, protect the margins in each of the industries, and help share the risks across the value chain. Partnerships must also include renewable energy companies and utilities to aid electrolytic hydrogen production. In places where CCUS retrofits may not be feasible, the price of electricity will influence the pace and cost of decarbonization of the industry. If a price on carbon is not achieved in the near-term, and renewable electricity prices continue to drop, then the economics of electrolytic hydrogen may become more attractive. Industries that use CO2, such as oil and gas, food and beverage, and pharmaceuticals can support the utilization of the captured CO2. Infrastructure, mechanical and electrical equipment, and automobile companies represent the biggest users of steel. Their participation will be vital for the use and long-term business viability of low-carbon steel.

Targets over the next five years should address immediate scale-up aided primarily by policies and then shift towards broader deployment driven by market dynamics and policies. Utilizing 45Q credits for the industry will protect profit margins of first movers and encourage cost-shares and partnerships. For this, the first large scale projects for hydrogen with CCUS or using electrolysis in each of the industry segments must be deployed in the next 2-3 years. Federal support for R&D and multiple pilot tests will provide additional immunity to first movers over the next 5 years.

III.E: Convergence Acceleration of Methanol

Methanol, especially bio-methanol, has a vital role to play in a low-carbon energy future. Since the technology for methanol production is well known and considerably mature, the biggest shifts will come from policy and regulatory changes to stimulate new markets and drive broader uptake. Nevertheless, reducing the cost of methanol production and energy efficient separation of methanol from water remain technological challenges that can be transformative to this industry. Moreover, finding low cost adaptation of current combustion systems to use methanol as the fuel and improve engine efficiencies remain as outstanding challenges. Lastly, for the case of bio-methanol, issues regarding the nexus of food, water, and energy must be addressed from both societal and policy perspectives.

Advances in non-thermal separation of methanol from its mixture with water to improved catalysis, along with intensification and potential modularization of chemical processes to handle distributed feedstocks to lower the energy and greenhouse gas intensity of methanol manufacturing are well suited to convergence of chemistry, engineering and supply chain logistics. The expansion of the methanol economy requires investments in infrastructure as well as advancements in combustion processes, including engines. To demonstrably improve efficiencies requires the focused collaboration of liquid fuel supply chain specialists along with auto and process manufacturers, to ensure a seamless and less expensive threshold for the methanol economy. One pathway to a zero carbon transportation fuel is through the expansion of the production capacity of bio-methanol. This reignites many of the challenges examined during the expansion of ethanol production for transportation and will require a careful and thoughtful integration of risks and unintended consequences on the planning and deployment.

Providing a pathway for the use of a substantial portion of the existing infrastructure for liquid fuels and internal combustion engine based technologies, methanol and zero carbon bio-methanol represent an excellent opportunity to be a transition fuel as the world moves to decarbonize. Addressing the crucial issues of competition for natural resources (water and land) with food as well as pathways to improve efficiency and reduce the energy footprint could expand methanol beyond a transitionary fuel.

IV. Circular Plastics and Chemicals

The circular materials economy, especially those components focused on plastics and chemicals, are heavily interdependent on the current energy systems, and they have a significant carbon footprint associated with them. As we progress to a low-carbon energy future, these segments are important areas to focus on and address comprehensively to reduce their energy, carbon and environmental footprint. While emerging science and technology developments have suggested much promise, the challenges are complex and strongly connected with human behavior and the implementation of regulations and incentives to drive social and commercial adoption [8] .

8The New Plastics Economy: Rethinking the Future of Plastics, Ellen Macarthur Foundation, 2017.; The New Plastics Economy: Catalyzing Action, Ellen Macarthur Foundation, 2017.

Figure 9. Word cloud responses on the opportunities and challenges in the circular plastics economy.

Figure 9. Word cloud responses on the opportunities and challenges in the circular plastics economy.

IV.A: Advanced Recycling of Plastics

One of the most significant opportunities in this area is that of advanced recycling or chemical recycling that can be economically advantaged because of its ability to use the significant sunk cost in plastics manufacturing infrastructure. Current barriers include the collection, cleaning (potentially addressed through behavioral, policy, regulation and last-mile intelligence) and energy / chemical intensity (science and technology) of the advanced recycling processes.

The convergence of chemical sciences and technology towards the breakdown and upcycling of manufactured plastics, along with digital and AI/ML technologies to address the last mile challenges, and connecting these with policy, regulation and education could provide transformational changes to Advanced Recycling. Concepts of advanced catalysis, green chemistry, distributed sensors and tagging, automation and robotics, along with policies such as Extended Producer Responsibility (EPR), enabling single-use recovery and life-cycle analysis, are keys to the success of these programs. Systems level integration will be definitional for advanced recycling of plastics. The evaluation of policy interventions in a systems framework that brings inputs from science and engineering along with social and behavioral sciences, connected and evaluated by regulatory, policy and business experts will be important.

The plastics waste management and recycling industry is a complex value chain and can be bottlenecked at various stages. Partnerships between plastics manufacturers (with expertise in manufacturing, and the energy and GHG impacts of resin production), processors, commercial and industrial users (with expertise in supply chain management), waste collection, reclaimers and recyclers are crucial for identifying and debottlenecking the value chain. Moreover, connecting these largescale industries with the invention, entrepreneurship, innovation and scale-up entities, along with policy experts and behavioral scientists, is crucial for a breakthrough in the advanced recycling space.

Important deliverables for rapid acceleration of advanced recycling include strategies for management of mixed waste streams to result in chemical recycling of polyolefins, PVC, and PS streams that break the challenge of energy impacts, greenhouse gas emissions and process economics. Moreover, identifying policy and behavioral approaches to increase the recycling rates from 10 to 25% and connect with technological developments to drive rapid upscaling of advanced plastics recycling across polymer families is desired, so that 100% of all plastics are recycled by 2050.

IV.B Increasing Penetration of Mechanical Recycling

Mechanical recycling remains the most cost-effective recycling option for most commodity plastics, especially PET and HDPE. Key challenges responsible for the poor rates of mechanical recycling lie with the poor separation of plastics, their inability to deliver high-quality products from multi-component streams, and down cycling of products due to the issue of fillers, additives and inks. Technologies for the efficient removal of additives, inks and fillers and the separation of multi-component and multi-layered films, policies focused on residential and commercial multi-bin solutions (such as in Japan and Europe), and technologies for improving polymer properties and therefore upcycling of mixed streams are important.

The convergence of chemical sciences and technology, along with integration of sensors, digital and AI/ML technologies, as well as advanced manufacturing, are important to improve the separation of plastics, address the issue of additives and fillers, and improve the overall efficacy of mechanical recycling. Delivering policy, regulation and education that address the sorting and cleaning of plastics, and minimizing of energy use and greenhouse gas generation during mechanical recycling, are important advances.

Partnerships between plastics manufacturers, processors, commercial and industrial users, waste collectors, reclaimers and recyclers are crucial. For instance, currently in many commercial municipal recycling facilities, the separation of plastics codes 3 through 7 and flexible grades of all plastics from household waste are avoided and the plastic waste is treated as a composite stream. Applying mechanical recycling to this composite leads to significant down cycling. Developing inexpensive technologies and processes to effectively separate these plastics and establishing supply chains for their reuse could be transformational. Likewise, establishing a digitally secure supply chain for commercial and industrial use of plastics could significantly improve recycling rates. Moreover, connecting these largescale industries with the invention, entrepreneurship, and innovation and scale-up entities is crucial for improving mechanical recycling.

Continued growth of mechanical recycling include strategies that improve the efficacy for plastic streams beyond PET and HDPE, and especially for mixed plastic and flexible plastic waste. Policy, incentives, education and behavioral approaches must complement improvements in technology and supply chain management to broaden the scope of mechanical recycling.

IV.C: Distributed Waste Processing

The generation of plastic waste (especially residential and commercial) is geographically distributed and the transportation of solid waste is expensive. Thus, there is a critical need for distributed and possibly modular recycling systems that are energy efficient, avoid down cycling and minimize greenhouse gas (GHG) emissions. The key challenges are managing low-quantities of mixed streams and ensuring that their processing has maximum flexibility while staying economically feasible.

Effective sorting technologies and modularized energy-efficient processing techniques are needed for separation and reprocessing of plastics, along with effective chemical methods to eliminate fillers and additives. These technologies and processes will strongly benefit from the convergence of chemical process technologies, along with integration of sensors, digital and AI/ML technologies, and advanced manufacturing principles. Additionally, understanding the role of improved regulation and consumer education could play a strong role in improving recycling and reuse rates.

Partnerships between waste collection (rural/municipal, commercial and industrial users), reclaimers, recyclers and local authorities are crucial to ensure the viability of distributed circular materials management. Connecting innovation around collection and sorting of plastic waste and intensified and distributed processes, with social scientists and policy experts is necessary.

While there has been significant acceleration in the development of integrated, intensified and modularized processes for various segments of the energy and chemicals industries, including natural products production, the issue of plastics waste and its management has not embraced these cutting edge processes and methods.

IV.D: Plastics to Hydrogen

Plastics are a significant repository for embedded energy, and the development of methods to extract this energy while minimizing or eliminating the generation of greenhouse gases is an outstanding challenge that has received significant interest from the scientific and technology communities. The utilization of that embedded energy is exemplified in the incineration of plastics and the use of that energy for heating or power generation. The challenge with the incineration approach is the large amount of greenhouse gases that is emitted. An approach that uses high temperatures, plasma or microwave energy to convert mixed streams of plastics into hydrogen and a combination of solid carbon and organic liquids (synthetic fuel) has been demonstrated scientifically and is in early stages of commercial development [9] .

Convergence of catalytic chemistry and process engineering towards the effective conversion of waste plastics to hydrogen and manageable carbon products in a cost-effective and environmentally-friendly manner at scale, especially working with realistic plastic waste streams, is necessary. The ability to handle or remove metals and inorganic materials from the plastic waste would be crucial for the success of such methods. This work will also benefit significantly from a developed infrastructure for the handling and use of the produced hydrogen, as well as markets for the produced carbon products. Implementation of protocols such as extended producer responsibility or a subsidy for the generation of “blue” hydrogen in these methods could significantly accelerate the progress.

The key partnership for this technology to advance includes plastic waste aggregators, process technologists, and the carbon and hydrogen value chains. This requires close partnership between catalytic chemists with chemical process engineers and potentially electrical engineers to ensure the integration of renewables with the process technology for generation of “blue” hydrogen. The impact of this work would be a mechanism to handle end-of-life for complex mixed waste streams of plastics at distributed locations and local energy storage through hydrogen and safe sequestration of carbon waste. Over the longer term, the success of this work will help expand the effective storage of renewable energy, the elimination of plastic waste especially for hard to manage mixed streams, and the sequestration of carbon as solid carbon products.

IV.E: Technology and Policy Roadmaps for Global Technology Collaborative

The issues of plastics waste are global and each geographical area must develop technology and policy roadmaps that are best optimized to the existing infrastructure, anticipated demographic changes, economic outlooks and market opportunities in regional areas. As identified previously, addressing consumer behaviors and ensuring appropriate consumer education is a high priority and must be addressed within each regional ecosystem. However, it has also become clear that many of the best scientific and technological solutions and policy advancements to address the circular plastics economy have transferability and are not necessarily unidirectional i.e., bidirectional transfer of solutions from developed and developing economies. Moreover, connecting the circular plastics ecosystems and the roadmaps developed for this with those developed for other areas of decarbonization is crucial.

D. Concluding Comments

In order to meet the “Net-Zero by 2050” goal, the transition to a lower carbon, affordable and reliable energy system must accelerate compared to the pace of change over the previous thirty years. This rapid acceleration of the energy transition will require significant, cost-effective, breakthrough technologies that are enabled by convergence science and engineering, a strong integration with existing energy infrastructure, and public and regulatory policies that will focus on measurable outcomes. Much of the science and technology enhancement will be enabled by rapid measurements of processes, their environmental impact, and efficiency. Moreover, the abundance of data that will emerge will be appropriate for data science tools to translate the data to business decisions. Much of this will be predicated on advances in manufacturing, as well as automation and robotics. The emergence of public policy and regulatory policy that respond to these changes, and changing societal norms on the environmental impact, as well as perception of risk, will be transformative. While the study here identified four pillars that will enable the acceleration of the transition, the underlying interactions across those pillars and the connective tissue of enabling technologies and policies will define the pace of the energy transition. Nevertheless, a significant challenge that the impending energy transition must confront is the issue of an aware public and a workforce that is ready to integrate broad and disparate issues of science, technology and societal changes, and yet be nimble to adopt advances from adjacent spheres of influence.

[1] Deployment of Deep Decarbonization Technologies: Proceeding of a Workshop (2019). http://www.nap.edu/read/25656

[2] https://www.chathamhouse.org/about-us/chatham-house-rule

[3] Temple J. (2018). The carbon-capture era may finally be starting, MIT Technology Review, February 20, 2018. https://www.technologyreview.com/2018/02/20/145489/the-carbon-capture-era-may-finally-be-starting/

[4] National Petroleum Council: Meeting the Dual Challenge A Roadmap to At-Scale Deployment of Carbon Capture, Use, and Storage (2019).

[5] Negative Emissions Technologies and Reliable Sequestration: A Research Agenda. National Academies of Sciences, Engineering, and Medicine; Washington (DC): National Academies Press (US); 2018 ISBN-13: 978-0-309-48452-7ISBN-10: 0-309-48452-9

[6] USDOE-EERE, Bandwidth Study on Energy Use and Potential Saving Opportunities in U.S. Petroleum Refining (2015)

[7] Robert Margolis, Colin McMillan, Parthiv Kurup, “Solar for Industrial Process Heat” SETO CSP Program Summit 2019 Oakland, CA March 19, 2019

[8] The New Plastics Economy: Rethinking the Future of Plastics, Ellen Macarthur Foundation, 2017.; The New Plastics Economy: Catalyzing Action, Ellen Macarthur Foundation, 2017.

[9] Nat. Catal. 3, 902–912 ( 2020) Jie, X., Li, W., Slocombe, D. et al. Microwave-initiated catalytic deconstruction of plastic waste into hydrogen and high-value carbons. https://doi.org/10.1038/s41929-020-00518-5