Almost 200 years after French physicist Jean Peltier discovered that electric current flowing through the junction of two different metals could be used to produce a heating or cooling effect, scientists continue to search for new thermoelectric materials that can be used for power generation.

Researchers writing in Nature Materials, however, say it is time to step up efforts to find new materials for thermoelectric cooling.

Bismuth tellurium compounds have been used for thermoelectric cooling for more than 60 years, and the researchers say the fact that there is already a commercial demand for the technology suggests better materials can expand the market.

“Most work is focused on high temperature materials for power generation, but there’s no market there yet,” said Zhifeng Ren, director of the Texas Center for Superconductivity at the University of Houston and corresponding author for the paper. “Cooling is an existing market, a billion dollar market, and there has not been much progress on materials.”

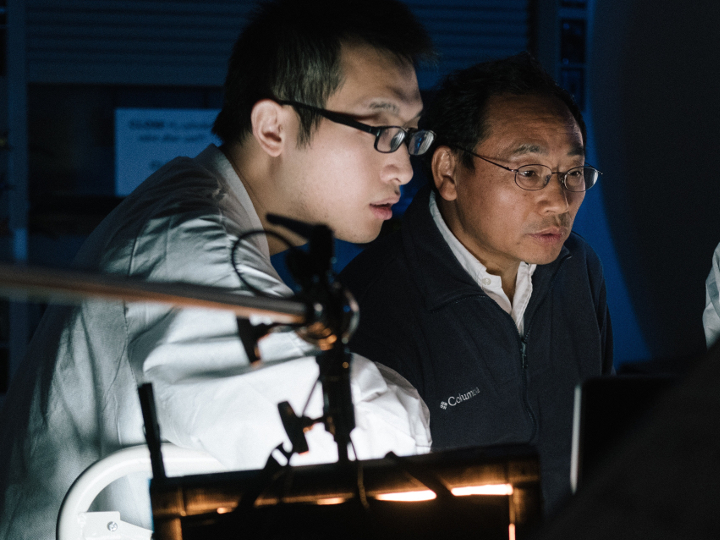

He and co-authors Jun Mao, a researcher at TcSUH, and Gang Chen, a mechanical engineer and nanotechnologist at the Massachusetts Institute of Technology, call for increased focus on the development of new advanced materials that work at or near room temperature.

The three were part of a group that in 2019 reported in the journal Science a new material that works efficiently at room temperature while requiring almost no costly tellurium, a major component of the current state-of-the-art material.

The material, comprised of magnesium and bismuth, was almost as efficient as the traditional bismuth-tellurium material. Work to improve the material is ongoing, Ren said.

Thermoelectric materials work by exploiting the flow of heat current from a warmer area to a cooler area, providing an emission-free source of energy. The materials can be used to turn waste heat – from power plants, automobile tailpipes and other sources – into electricity, and a number of new materials have been reported for that application, which requires materials to perform at higher temperatures.

Thermoelectric cooling modules have posed a greater challenge because they have to work near room temperature, making it more difficult to achieve a high thermoelectric figure-of-merit, a metric used to determine how efficiently a material works. Thermoelectric materials used for power generation more easily achieve a high figure-of-merit because they operate at higher temperatures – often around 500 Centigrade, or about 930 Fahrenheit.

But there are also advantages to thermoelectric cooling devices: they are compact, operate silently and can almost instantaneously switch between heating and cooling, allowing precise temperature control. They also operate without generating ozone-damaging greenhouse gases.

They are used mainly for small applications, including the transport of medical supplies and cooling laser diodes.

“For large-scale cooling devices, a compressor is still more efficient,” said Ren, who is also M.D. Anderson Chair Professor of Physics. “For smaller systems or for any cooling application requiring very precise temperature control, regular compressor-driven cooling is not as good.”

But the discovery of new and better materials could expand the market.

“If you can find materials with a higher figure-of-merit, you can have a very competitive performance for refrigerators or even air conditioning,” Ren said. “It’s not there yet, but I don’t see why it cannot be in the future.”