The Valley of Death

Other researchers face a more circuitous route to commercialization. The stage between proof of concept, a prototype and the marketplace can be so tricky that inventors call it the Valley of Death.

It’s real, and the UH Division of Research decided several years ago to tackle it head-on. The Technology Gap Fund was launched in 2013 for faculty members who have developed technologies almost ready for commercialization, issuing grants to cover expenses during the transition between proof of concept and attracting outside investment.

So far, nine grants have been issued through the fund, each worth up to $50,000.

After two years of work, Jason Eriksen, associate professor of pharmacology, and Craig Vollert, a doctoral student set to graduate this summer, are almost there, and $40,000 in gap funding last year pushed them closer to the finish line.

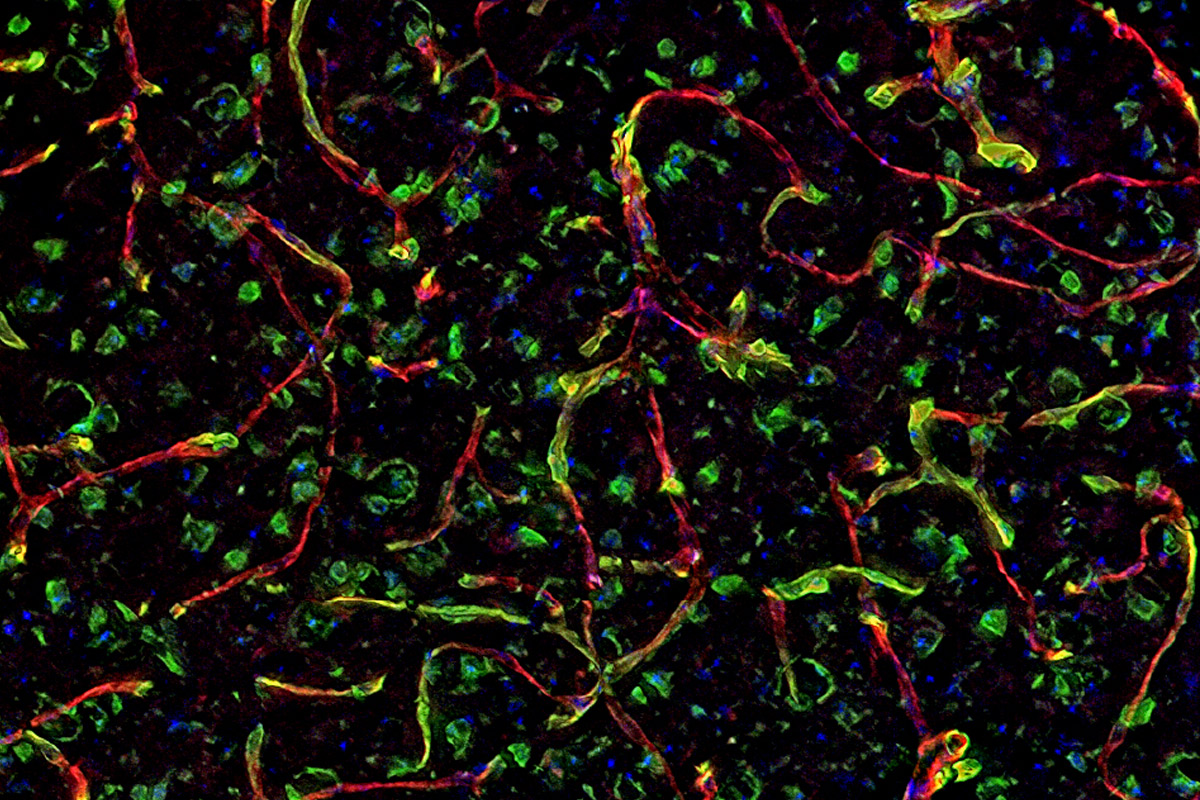

By then, they had the idea and proof of concept – a chemical treatment to make staining tissue samples more effective. It had been developed after Eriksen, working under a grant from the National Institutes of Health to study blood vessels in people with Alzheimer’s disease, tried to stain the vessels in a sample.

“I found, to my horror, that it didn’t work,” he says.

He needed answers.

Most medical tissue samples are preserved with formaldehyde or a similar compound, and Eriksen discovered that formaldehyde chemically changed the tissues, masking the blood vessels.

He started trouble shooting, coming up with a compound that could remove the chemical modification. It worked, but he didn’t know why it worked. By then, Vollert was on the case. Soon two researchers from the UH College of Natural Sciences and Mathematics, Willy Moree and Steven Bark, an assistant professor of biology and biochemistry, were in on the hunt as well.

Eventually, Eriksen says, they moved from one compound that could solve the problem to deciphering the principle behind it. That allowed them to find scores of other compounds, known as formaldehyde scavengers. All are readily available.

“There are billions of samples sitting in labs and hospitals where we think this would be a great technology,” Eriksen says.

One problem was solved. But figuring out how to make the chemical treatment available to other researchers was a different kind of puzzle.

They filed for a patent and founded a biotech company, Teomics LLC, with Vollert serving as CEO, a task he will assume full time after completing his Ph.D. Moree is Chief Scientific Officer. Eriksen and Badri Roysam, chairman of the Department of Electrical and Computer Engineering, are involved, too, although they are keeping their day jobs.

To prepare for the challenge, Vollert took a class in entrepreneurship at Rice University in 2014, and the following year began working with Red Labs, the technology accelerator run by Bauer College of Business.

The Technology Gap Fund helped them make the final push, moving the technology from a prototype to a full product, which can be added to commonly used staining compounds.

“The big benefit of our technology is for researchers,” Eriksen says. “It’s an easy solution to a difficult problem.”

Technology gap funding is also helping Pollonini, the engineering technology professor working to prevent bedsores, prepare his concept for commercial production.

Research showed tighter monitoring of blood flow would be effective. “We looked at blood perfusion, minute-to-minute, in real time,” he says. “If you see that change over time, the risk for bedsores increases significantly. But if you can detect bedsores earlier, they are treatable with minimal intervention.”

The sensors he had developed to monitor blood flow in free flap surgery are compatible with any type of tissue, Pollonini says. But the prototype developed for surgery was too small and too thick to use in detecting when a patient is at risk of bedsores.

A $50,000 gap fund grant last summer covered the cost of building a prototype – larger and thinner than the prototype intended for breast reconstruction surgery, and embedded with more sensors. It should be ready by mid-summer, he says.

That won’t be the final step. The technology still must be validated by testing and clinical trials.

Pollonini also serves on a Division of Research committee overseeing the University’s intellectual property, and he has noticed the growing emphasis, both as a researcher and from the administrative side.

“We’re getting busier and busier in protecting our intellectual property,” he says. Beyond that, the University is offering more support for faculty start-ups, including more space – and a wet lab – for startups to use at the Energy Research Park.

Faculty inventors stand to profit personally from their work, Pollonini says, but he points to a bigger benefit. “The institution benefits from royalty income, and that eventually goes back to research at a time when federal (research) funding is becoming challenged,” he says.

Next Story:

A Role for Students

Professor of civil and environmental engineering, developed a “smart” cement that can sense changes in the environment around it, potentially averting oil spills, collapsing bridges and other disasters.